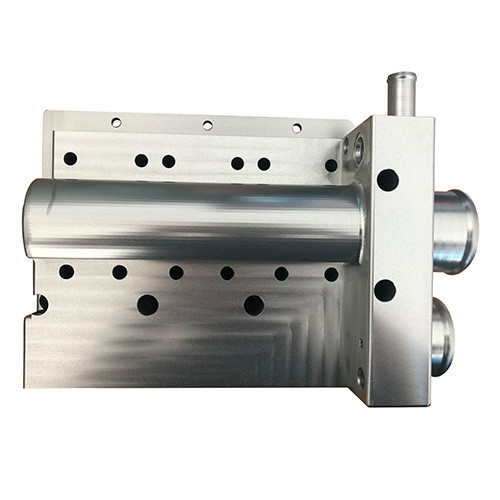

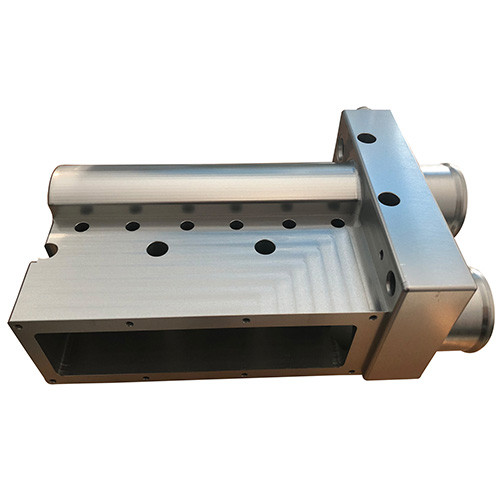

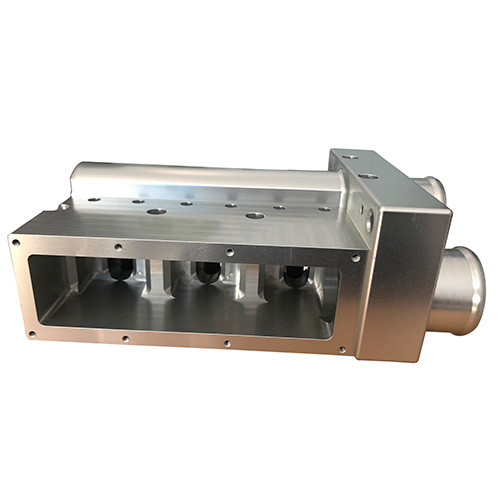

4-Axis cnc machining Fuel Cell Parts&Accessories,Machining services of medical components made of plastic composites and titanium.

Machining capabilities include manual milling, 4-axis CNC machining, 5-axis CNC machining, lathe machining, CNC turning, grinding, wire EDM, and welding. Capable of achieving tolerances up to 0.0002" for milling services and 0.0001" for turning and wire EDM services. Other materials worked with include fiberglass composites, magnesium castings, stainless steel, tungsten, sand castings, investment castings, and aluminum. Also available are plating, painting, powder coating, heat treating, pressure testing, broaching, and ram EDM services.

Product Description

Part Name

4-Axis Cnc Machining Fuel Cell Parts&Accessories

OEM&ODM

Custom according to drawing or sample

Material

Steel

12L14,Y15,Q235,20# steel,35# steel,45#,65Mn steel,sus201,sus302,sus303.sus304,sus316,etc

Brass

C36000(C26800), C37700(HPb59), C38500(HPb58), C27200(CuZn37), C28000(CuZn40),Beryllium Copper,etc

Aluminum

Aluminum 5052,6061,6063,7075, etc

Finish Treatment

zinc/nickel/tin/chrome/brass/copper plated,black oxide coated,passivated,KTL coating,anodise,sandblast,powder coat,painting,etc

Types

Custom,various types

Processing

cnc turning or cnc milling

The methods of delivery

Express(DHL,EMS,TNT,UPS or Fedex),By sea(EXW,FOB,CIF),By air

Tolerance

+/-0.02MM

Minimum Order Quantity (MOQ)

Small Orders Are Acceptable

Application

Automation accessories

Quality Control

RoHS tester, Callipers, Salt Spary Tester, 3D Coordonate Measuring Instrument

What's advantages of our factory?

1. Provide OEM&ODM service and assembling service,since 2007.

2. One-stop purchasing service:stamping part,cnc milling part,cnc turning part,auto lathe part,spring,shaft,hook,fastener,etc

3. The 2nd tier supplier of Huawei,social responsibility factory audit passed.

4. Product certification:RoHS,HE report available.

5. Management certification:ISO9001:2015 and IATF16949 passed.

6. Various material are acceptable:iron,stainless steel,brass,copper,bronze,aluminum,plastic,etc

7. Can help customers to save cost by doing the structure design and improving the function and safety of products.

Packaging & Delivery

Packaging: One piece in a foam bag, 10 KGS in a carton. Delivery: The samples delivery is about 15 days and the lead time for mass production is about 30-45 days.Low cost custom oxidation aluminium milling parts