project managerment

PTJ cnc machining Project Managerment

|

RFQ 1: sales collect all information and drawing, making quotation sheet to quotation engineer 2: the quotation will be provide within 1-2 days. |

|

PO 1: Project kick-off with customer purchase order and down deposite payment.( Sales collect Po, and making invoice) 2: sales collect all confirmed project informations to project engineer. 3: Project engineer make the new parts machining notice, time schedule, and project managerment files. 4:all files to this new project will submit to the Field Engineer |

|

Parts Making Meeting 1: The project engineer, Field Engineer and tool manager will hold a meeting evaluate this new project 2: Making the Suggest for manufacturability report and Parts flow report to customer. 3: After the Suggest for manufacturability report, Parts flow report confirmed, Parts Manufacturing will start. |

|

Schedule 1: After customer confirmed, the exact time schedule of Parts Manufacturing will be submit to customer. And it will be updated every week. 2: If customer has more than one projects in our company, Overview sheet will also submit to customer and updated every week. |

|

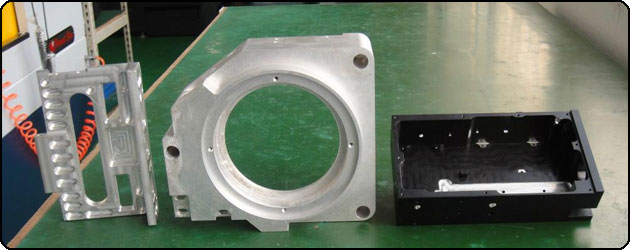

Parts Manufacturing 1: one day before the manufacturing parts, the new parts notice will be submitted to purchase department. The ordering of materials will be arranged in advance. 2: After first parts trial, the sample will be sent to customer. Meanwhile the QC report, parts trial process report will be provided within 3 days. 3: All the issues and solution to the sample will be included in parts correction report. And this report will also be send out with 2 or 3 days! 4: After customer received the samples and communication with our project engineer, the Modification will start. the samples will be sent again. 5: After the parts approved, the final parts inspection, materials running on the precision machine, and cleaning will be done. |

|

Parts delivery 1: Tool management department will check the parts as parts final inspection report. 2: parts will go to cnc machine and running without production. 3: All the files like 2d, 3d, steel certification, Photo, inspection report will be made in CD. 4:Shipping item usually FOB, EXW, ( we can also help to introduce forwarder do DDP item) |

|

To make sure that the parts can run well in customer`s project structure ,we trial the parts in a scientific parts trial A: First trial for testing parts micro exterior and the problem that the parts may have. B: Second trial for solving the problem which happened in the first trial.

|

|

|

A: Every metal parts of cnc machining should be cleaned.  B: Parts Final insepction report (with drawing) |

|

|

|

|

|

C:Each customer's project parts will be produced an additional 5-8, and then have a dedicated project management room for backup and preservation.  |

Parts packing before Shipping |

Before packing

In the packing  After packing |

After sales service |

Owning the technical adviser and cooperater cnc machining factory in Swenden,England,and The Netherlands. Professional engineer docking go to customer for solving the problem when complain appeared. PTJ is responsible for remaking new parts when the broken caused by PTJ. For serious problem,PTJ provides return, exchange service. |

|

|

→ Contact Us To Get A Free Quote Right Now Get start to make your machines be operated quickly and easily |

|