machining alloy

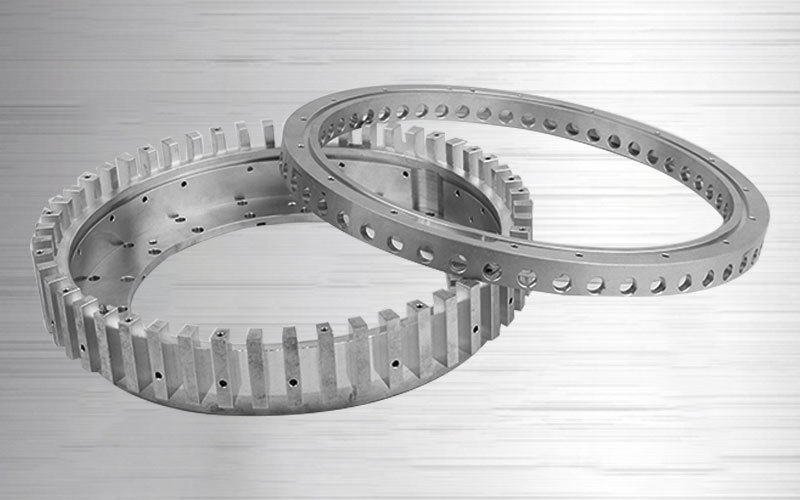

Alloy Steel CNC Machined Parts

|

|

|

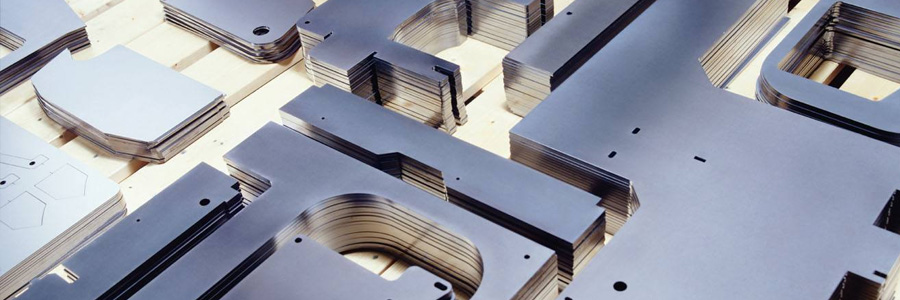

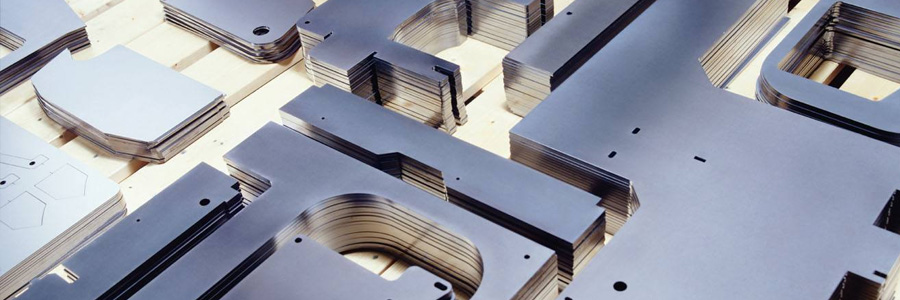

PTJ has a reputation for successfully machining the metals other producers prefer not to handle. Customers can confidently design with new materials, secure in the knowledge that PTJ can machine even the most exotic, high-temperature alloys for a quality, cost effective result.

Dozens of Experienced Machinist

After 10+ years in the industry, we’ve built a staff of machining and engineering experts who recognize the manufacturing challenges in a new material before they become costly production delays.A complete in-house tooling capability creates customized tools precisely for the properties of the metal being machined.

You are invited to tap into this valuable manufacturability resource at no obligation. Contact us with details on your metal alloy machining application for our expert assistance.

Steel Alloy Machining Characteristics

The main alloying elements of alloy steel are silicon, manganese, chromium, nickel, molybdenum, tungsten, vanadium, titanium, hafnium, zirconium, cobalt, aluminum, copper, boron, rare earth and the like.

Quenched and tempered steel

- Medium carbon alloy steel with low alloying elements;

- High intensity;

-

Used for high temperature bolts, nut materials, etc.

Quenched and tempered steel refers to steel for quenching and tempering after quenching into martensite and tempering in the temperature range of 500~650 °C.

Springsteels

- The carbon content is higher than the quenched and tempered steel;

- After quenching and tempering treatment, the strength is higher and the fatigue strength is higher;

-

For spring materials.

Rolling bearing steel

- High carbon alloy steel, high alloy content;

- Has high and uniform hardness and wear resistance;

-

For rolling bearings.

Bearing steel is steel for the manufacture of various types of rolling bearing rings and rolling elements

Alloy tool steel

- High carbon alloy steel with low alloying elements.

- High hardness and wear resistance.

-

Good stability, good machining performance

View all products on parts gallery page

Common Material Cost Comparison

|

Type |

General Characteristics |

Alloy |

Common Applications |

Tolerances for a 1/2" Dia. Bar |

Material Cost Factor |

Machining Cost Factor |

|

Aluminum |

Designed for machining |

2011 |

Electronic hardware, endless commercial products |

Cold finish +/-.0015 |

3.8 |

.6 |

|

Stainless steel |

Designed for machining, non- magnetic |

303 |

Electronic hardware, automotive, aerospace, medical instruments, and many applications requiring corrosion resistance |

Cold finished +/- .002 |

1.9 |

2.7 |

|

Brass |

Strength, corrosion and wear resistance, and excellent machinability |

C35300 |

Well suited for parts with knurling or threading |

+0015 |

3.5 |

.07 |

|

Steel |

Designed for excellent machinability. Case hard only |

12L14 |

Endless commercial products; probably more pounds used in turned products than any other material |

Cold drawn 0 |

1 |

1 |

|

Titanium |

High strength, light weight, good bio- compatibility |

Ti-6Al-4VEli |

Medical implants |

Ground & polished +/-.002 |

30.2 |

6 |

|

Magnesium |

High strength, light weight, good bio- compatibility |

Mg17Al12 |

Die casting |

Ground & polished +/-.002 |

3-5 |

7 |

Are you already thinking of availing cnc machining service? We can be a good services. We are a team of skilled professionals, who have a huge experience in providing quality metal cnc machining services. To know more about our services, please get in touch with our experts today. You can reach out to us both, via phone, as well as email. Give us a call on +86 15118255600, or simply mail us your requirements at sales@pintejin.com.

|

|

→ Contact Us To Get A Free Quote Right Now Get start to make your machines be operated quickly and easily |

|