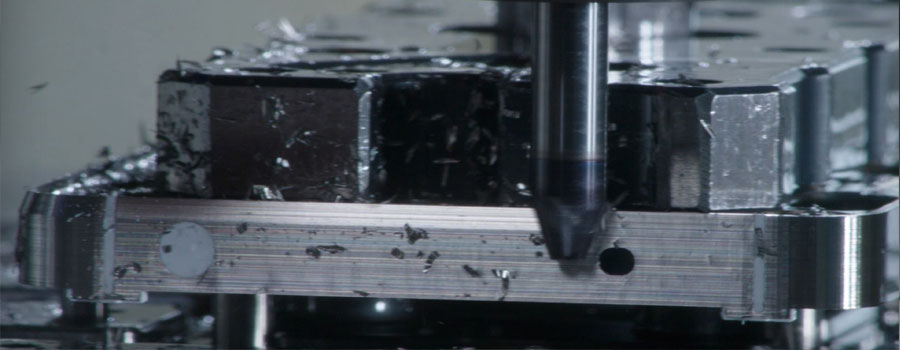

turn-mill combination

Composite machining is one of the most popular machining processes in the world of machining. It is an advanced manufacturing technology. Composite machining is the implementation of several different machining processes on a single machine. Composite processing is the most widely used and the most difficult is the combination of turning and milling.

The turning and milling combined machining center is equivalent to a combination of a CNC lathe and a machining center.

If you want to run your business to get cnc machining parts, below some basic information you may need to know.

-

The Introduction to turning and milling

- The advantage of turn-mill combination

- The characteristics of turn-mill combination

- The difference between simple machining and composite machining

Introduction to turning and milling

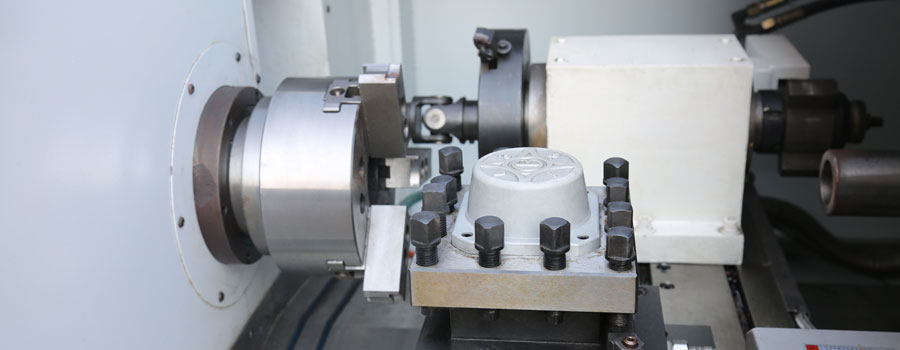

Turn-milling machine tools are the fastest growing and most widely used CNC equipment in multi-tasking machines. Machine tool compounding is one of the important directions in the development of machine tools. The compound machine tool also includes various forms such as turning and milling compounding, turning and milling compounding, milling and grinding compounding, cutting and 3D printing compounding, cutting and ultrasonic vibration compounding, laser and stamping compounding, etc. The purpose of compounding is to make a machine tool more Functionality, multi-tasking can be done in one setup, improving machining efficiency and machining accuracy.

Turn-milling machine tools are the fastest growing and most widely used CNC equipment in multi-tasking machines. Machine tool compounding is one of the important directions in the development of machine tools. The compound machine tool also includes various forms such as turning and milling compounding, turning and milling compounding, milling and grinding compounding, cutting and 3D printing compounding, cutting and ultrasonic vibration compounding, laser and stamping compounding, etc. The purpose of compounding is to make a machine tool more Functionality, multi-tasking can be done in one setup, improving machining efficiency and machining accuracy.

The advantage of turn-mill combination

Compared with the conventional CNC machining process, the outstanding advantages of composite machining are mainly reflected in the following aspects.

- Shorten the manufacturing process chain and increase production efficiency. Turning and milling combined machining can complete all or most of the machining processes in one loading, thus greatly shortening the product manufacturing process chain. This reduces the production assistance time due to the change of the loading card, and also reduces the manufacturing cycle and waiting time of the tooling fixture, which can significantly improve the production efficiency.

- Reduce the number of clamping and improve machining accuracy. The reduction in the number of times of loading avoids the accumulation of errors due to the conversion of the positioning reference. At the same time, most of the turning and milling composite processing equipment has the function of online detection, which can realize the in-position detection and precision control of the key data in the manufacturing process, thereby improving the processing precision of the product.

-

Reduce floor space and reduce production costs. Although the price of a single unit for turning and milling combined processing equipment is relatively high, the overall fixed assets can be effectively reduced due to the shortening of the manufacturing process chain and the reduction of equipment required for the product, as well as the reduction in the number of fixtures, workshop floor space and equipment maintenance costs. The cost of investment, production operations and management.

The characteristics of turn-mill combination

- The turning and milling composite machining center uses a high precision built-in spindle;

- Free-moving operation panel improves work efficiency;

- The model mainly produces high-speed processing of various small parts and complex parts in large quantities, and diversified processing;

- Especially the slender and complicated process can be processed in one time, and the automatic feeding device can be configured to improve the efficiency;

-

Material details: cutting, copper, iron, aluminum alloy, stainless steel, Teflon and other materials.

The difference between simple machining and composite machining

- The turning and milling combined machining center is a machine tool that can perform turning and milling with B-axis linkage and C-axis linkage. It can be said that all or most of the machining of a part can be completed on the turning-milling compound machine, so it is also called a small production line. .

- For a five-axis machining center, it can only be milled and cannot be machined. Therefore, there are many limitations in the processing, the turning and milling compound can cover the processing of the five-axis machining center, but the five-axis can not be processed by the turning and milling composite.

|

|

→ Contact Us To Get A Free Quote Right Now Get start to make your machines be operated quickly and easily |

|