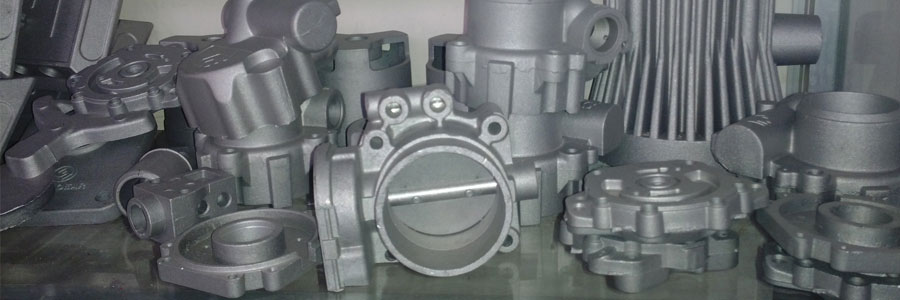

Special points of the aluminum die casting process

Special points of the aluminum die casting

| Introduction of aluminum alloy die-casting factory, mastering the chemical properties of zinc alloy die-casting parts. In the process of degreasing or etching, if strong acid or alkali is used, it will cause foaming and peeling of the coating during the electroplating process, thus affecting the plating parts. The yield is so low that it is not possible to use strong acids or bases. |

Aluminum alloy die-casting plant accelerates the bonding speed of zinc alloy die-casting parts before plating and slot plating. After removing the oil stain on the surface of zinc alloy die-casting parts, and immediately after the oxide film, the parts are placed in the plating tank for electroplating to avoid surface regeneration. An oxide film, or hydrate, affects the adhesion of the coating.

Aluminum alloy die-casting plant accelerates the bonding speed of zinc alloy die-casting parts before plating and slot plating. After removing the oil stain on the surface of zinc alloy die-casting parts, and immediately after the oxide film, the parts are placed in the plating tank for electroplating to avoid surface regeneration. An oxide film, or hydrate, affects the adhesion of the coating.

The aluminum alloy die-casting factory said that the development of zinc alloy die-casting molds in traditional stainless steel products has begun to expose its drawbacks. Its quality commitment has begun to be questioned, and its channel price system has been in a relatively transparent state. Jinsheng Zinc Alloy Processing Technology Color Steel The protective window absorbs the advantages of the current door and window.

It is a new product with unique functions and its own zinc alloy processing technology security window. It is the third generation replacement of protective window. It integrates safety and aesthetics. It adopts unique welding-free assembly line operation and combined shuttle structure. Accepting the baptism of the market, in line with the needs of the market and consumers, its birth will be an epoch-making revolution in the history of protective windows.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off