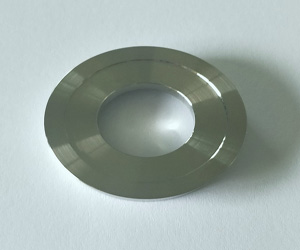

CNC Sheet Metal Operation Walkthrough

Sheet metal is an essential material in the vast realm of manufacturing and fabrication, playing a pivotal role in industries as diverse as aerospace, construction, automotive, and electronics. The advent of Computer Numerical Control (CNC) technology has significantly transformed the way we work with sheet metal, offering precision and automation that were once inconceivable. In this comprehensiv...