The huge energy played by the 5-axis linkage machining field - PTJ Manufacturing Shop

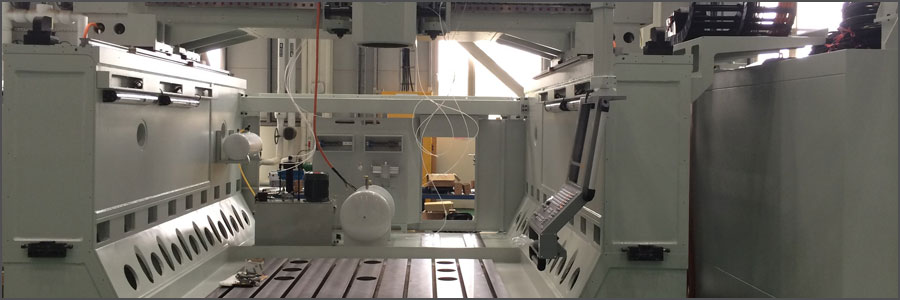

5-axis linkage machining

| 5-axis simultaneous machining produces powerful energy during the manufacturing process when complex machining or complex multifaceted parts are required. |

This applies to all types of industries in manufacturing, including: medical, optical, energy, aerospace, optoelectronics, automotive, electronics, communications, security, robotics, drones, general manufacturing, and more. 5-axis simultaneous machining is used for parts that require precise rotary machining, such as turbines and impellers, where contoured surfaces can be easily transitioned to produce the highest quality parts; this is the level of quality that current 3-axis machining cannot.

This applies to all types of industries in manufacturing, including: medical, optical, energy, aerospace, optoelectronics, automotive, electronics, communications, security, robotics, drones, general manufacturing, and more. 5-axis simultaneous machining is used for parts that require precise rotary machining, such as turbines and impellers, where contoured surfaces can be easily transitioned to produce the highest quality parts; this is the level of quality that current 3-axis machining cannot.

The following are some of the differences between 3-axis machining and 5-axis machining: Traditional 3-axis machining systems may require additional setup and additional preparation for complex parts. The 3-axis machining system moves on the X, Y and Z axes, providing only lateral and longitudinal movement; however, 5-axis simultaneous machining adds rotation to the A and B axes while providing crossover X, Y and Z axes. motion. This allows parts to be machined from all different angles in a single setup. Other differences between 5-axis simultaneous machining and 3-axis machining include:

- 5-axis simultaneous machining system can process complex shapes faster.

- The final product has higher accuracy.

- 5-axis simultaneous machining makes it easier to machine places where the 3 axes are difficult to reach.

- It can shorten production time and shorten turnaround time.

- With a high-capacity workbench, can rotate faster, and can easily handle heavier parts.

- Create a smoother, higher quality surface finish.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off