Division of CNC Lathe Machining Process - PTJ Manufacturing Shop

Vertical cnc machining Center Disadvantages

|

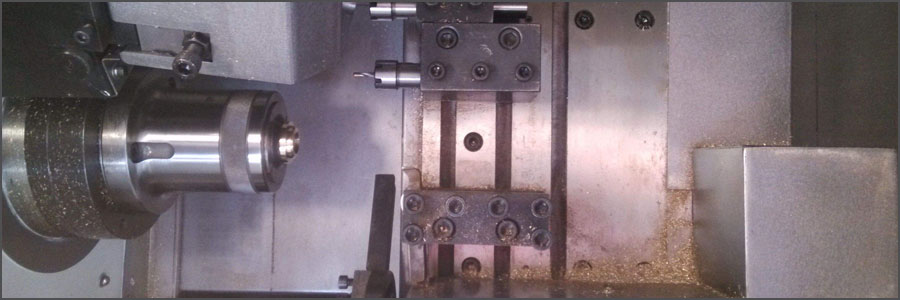

In the machining parts of CNC lathes, the process should be divided according to the principle of process concentration, and most or even all surfaces should be processed as much as possible under one clamping. |

Depending on the structural shape of the part, the outer garden, end face or inner hole clamp is usually selected, and the design basis, process reference and programming origin are guaranteed as much as possible. In mass production, the following two methods are commonly used to divide the process:

Depending on the structural shape of the part, the outer garden, end face or inner hole clamp is usually selected, and the design basis, process reference and programming origin are guaranteed as much as possible. In mass production, the following two methods are commonly used to divide the process:

- According to the surface of the part processing. The surface with higher positional accuracy is arranged under one clamping, so as to avoid the installation error caused by multiple clamping affecting the positional accuracy.

- Divided by rough and fine processing. For parts with large blanks and high machining accuracy, the roughing and finishing vehicles should be separated into two or more processes. The rough car is arranged on a CNC lathe with lower precision and higher power, and the finishing car is arranged on a CNC lathe with higher precision.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about Cnc Machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off