How to calculate speed and feed in CNC programming cutting - PTJ Shop

Speed and Feed

| Each tool takes different processing parameters for the material being processed. In the field of milling, toolmakers have developed more targeted coating technologies by optimizing tool materials to increase machining efficiency. |

By combining the various elements in the material, we can see thousands of machinable raw materials. To process these materials, we must know the processing properties of the material and know how it should be optimized.

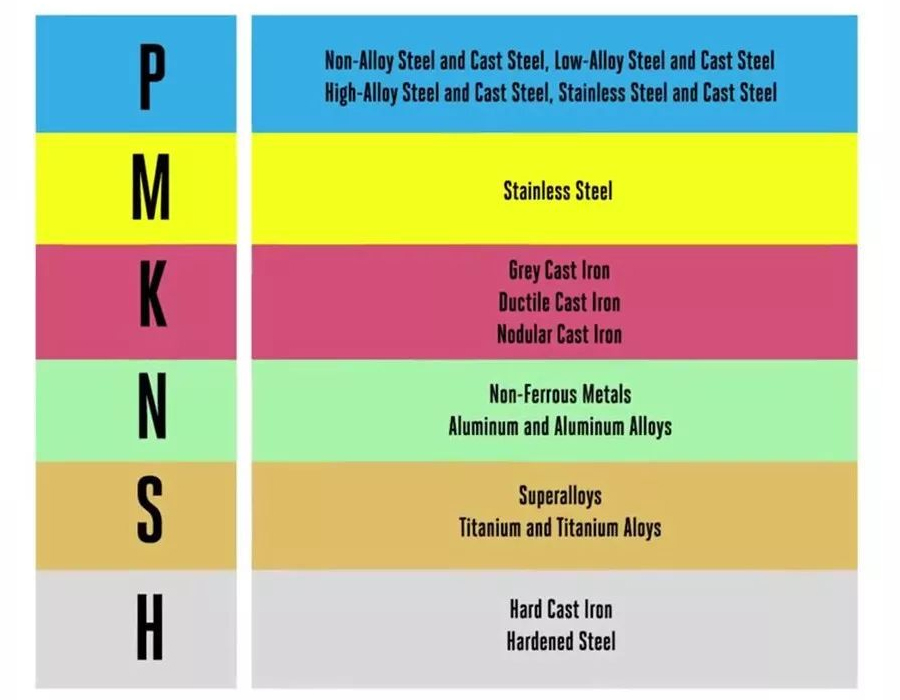

The grouping of materials to which the workpiece is processed:

According to ISO 531:1966 international standard

A total of 6 types of materials that can be processed

they are, respectively:

- Steel material represented by P;

- Stainless steel material represented by M;

- The cast iron material represented by K;

- Non-metallic materials represented by N;

- High temperature material represented by S;

-

High hardness material represented by H;

Tool manufacturers make smaller classifications of materials in these broad categories based on the tensile strength and hardness of the material. If we can't find the processing performance parameters of the materials to be processed in these sub-categories, the most feasible way is to consult the tool suppliers, I believe they are happy to help you solve this problem.

Calculation formula

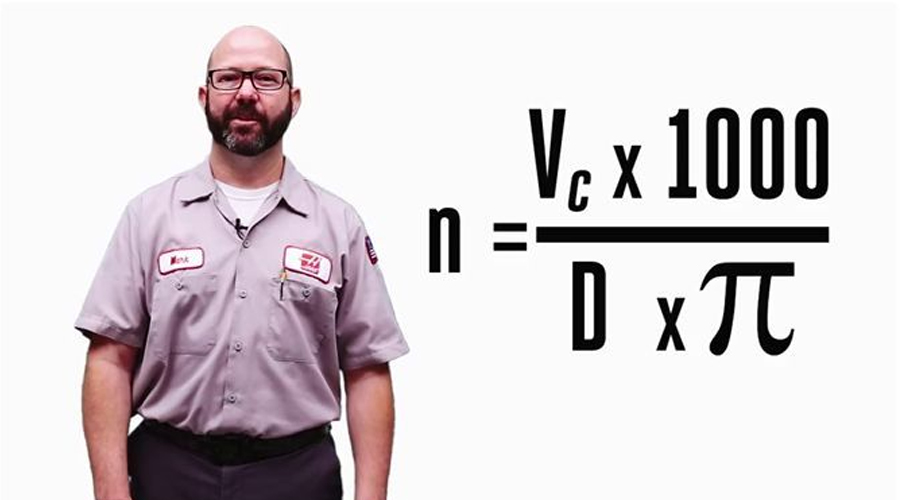

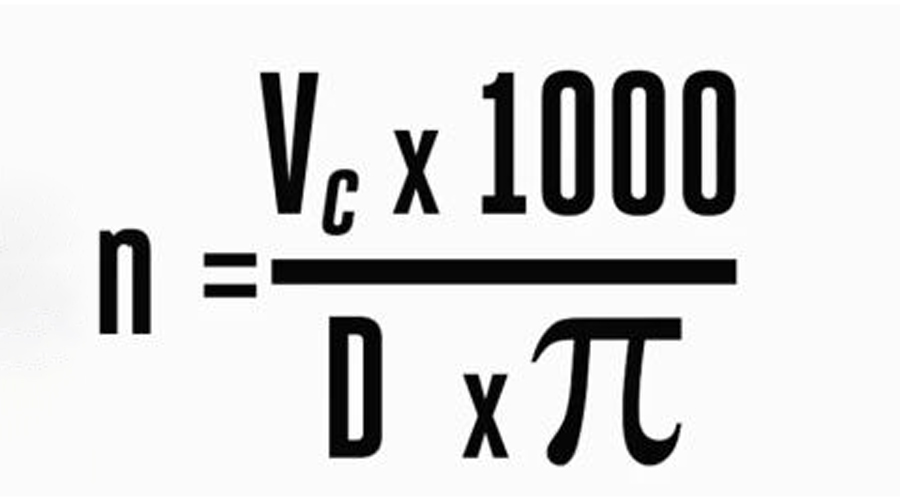

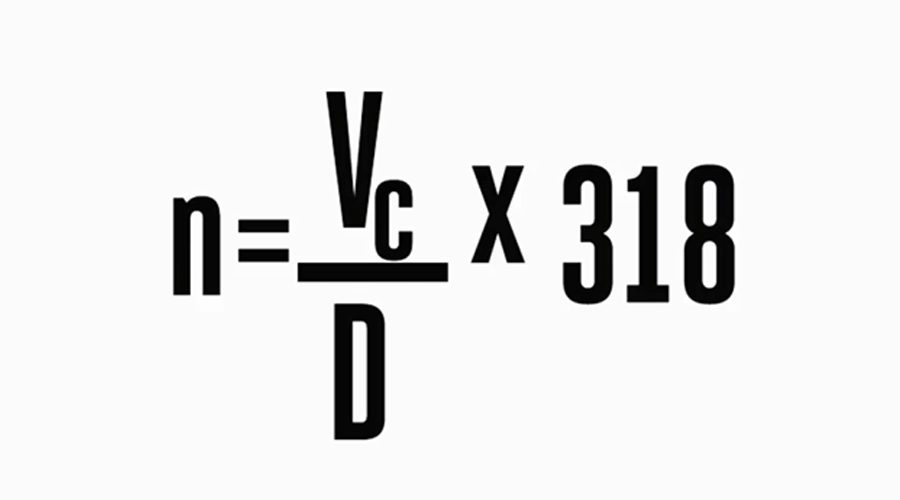

We usually see the following formula in the tool manual.

Before saying this formula, think back to the formula we have learned about the perimeter of the circle:

C (circumference) = π (pi) * d (diameter)

According to this formula, we can conclude that for a tool with a diameter of D, the distance traveled by the outermost point of the tool is:

π *D

Then, when the tool rotates at a frequency of n revolutions / 1 minute, the distance traveled is:

n*π *D

According to the formula of time (T) × speed (V) = distance (S ), the speed Vc of the tool at the outermost point of the tool is obtained at any point in time during this time:

Vc=(n*π *D)/1

The following formula is obtained by conversion:

n=Vc/(π *D)

note! Our tool uses millimeter (MM) as the unit, so the unit of speed Vc in the previous formula is: mm/min.

After the length conversion (1m = 1000mm), we have this common formula:

After the simplification of the equation, we have our final version of the formula:

note!

Here the unit of D (tool diameter) is still MM (mm), and the unit of Vc (line speed) becomes: M/min (m/min)

This formula is also applicable to turning machining, in turning, except that D here represents the blank diameter.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off