Precision machining subsequent process-heat treatment is very important - PTJ Manufacturing Shop

precision machining subsequent process-heat treatment

| There are many subsequent processing techniques commonly used in cnc precision machining, such as heat treatment and surface treatment. These machining processes are designed to make precision parts more practical. |

Next, PTJ Manufacturing Shop will focus on the importance of analyzing the subsequent heat treatment of cnc precision machining:

Next, PTJ Manufacturing Shop will focus on the importance of analyzing the subsequent heat treatment of cnc precision machining:

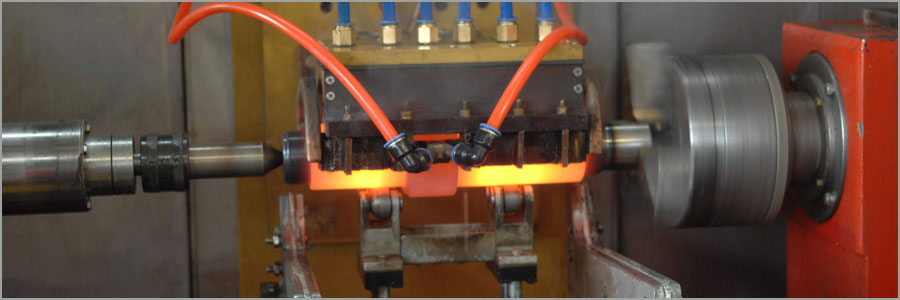

The heat treatment includes three stages of heating, heat preservation and cooling. The main factors that play a role in heat treatment are temperature and time.

Heat treatment is to heat the steel to a certain temperature in the solid state, carry out the necessary heat preservation, and cool to room temperature at an appropriate speed to change the internal structure of the steel to obtain the desired properties.

In cnc precision machining, heat treatment is to improve the mechanical function of mechanical parts, to ensure that the processing quality meets the needs of commodity use.

The importance of cnc precision machining heat treatment is as follows:

- Its purpose is to change the internal structure of steel to improve the performance of steel.

- Through the appropriate heat treatment, the mechanical properties of the steel can be significantly improved, and the service life of the machine parts can be prolonged.

- The heat treatment process can not only strengthen the metal material to fully exploit the material performance potential, reduce the structural weight, save materials and energy, but also improve the quality of mechanical products and greatly extend the service life of machine parts.

- Appropriate heat treatment process can eliminate various defects caused by hot working processes such as casting, forging and welding, refine grains, eliminate segregation, reduce internal stress, and make steel structure and performance more uniform.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off