Four methods for improve the automatic machining accuracy

Improve the automatic machining accuracy

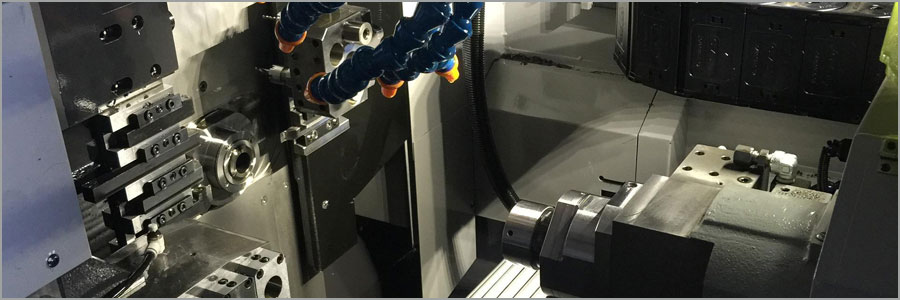

| How to improve the precision of automated precision machining? Many cnc processing manufacturers are thinking about the method. In the field of machining, in order to meet the requirements of some special products, the machine shop has to make some relative measures to achieve the user's requirements, but whether it is measures or solutions, we must pay attention to correctness, then, come together Learn how to improve the machining accuracy of automated parts. |

Solve the impact of machine tool drive on workpiece machining in the process system:

Solve the impact of machine tool drive on workpiece machining in the process system:

- Eliminate the drive gap

- Appropriate reduction of links to external links and internal links, shortening the drive chain

- Improve the performance and accuracy of the transmission accessory

Solve the effects of thermal deformation of the process system:

- Stabilize the heat balance of the process system

Automated parts solve the impact of process deformation on the machining of workpieces:

- Improve the rigidity of machine parts and tools

- Improve the rigidity of the workpiece

- When assembling the workpiece for precision machining, it is necessary to use the clamping tool reasonably.

Internal stress error solution:

- Reasonable design of part structure

- After the workpiece is precision machined, it is heated in the furnace to a certain temperature and cooled to eliminate internal stress.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off