What factors affect the surface roughness of machined parts?

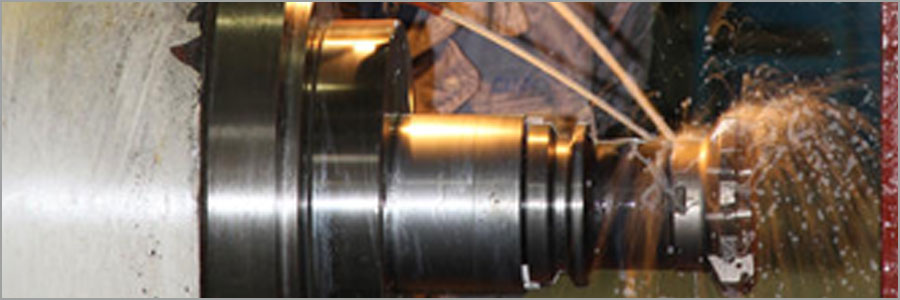

surface roughness of machined parts

| PTJ Manufacturing Shop is a professional manufacturer dedicated to the processing of high-quality precision parts. It is one of the few high-tech enterprises in Shenzhen that has the qualification of auto parts processing. It is based on the medical, optoelectronic and communication industries, and develops automobiles. precision machining services for man-machines, intelligent robots and office automation parts. |

We have summarized for you what factors affect the surface roughness of machined parts. Let's take a look at what factors affect the surface roughness of machined parts.

We have summarized for you what factors affect the surface roughness of machined parts. Let's take a look at what factors affect the surface roughness of machined parts.

First of all: the reason for the rough surface

1.Scales: When cutting high-speed steel cutters at low or medium speeds, such as low carbon steel, medium carbon steel, stainless steel, aluminum alloy, etc., often produce scaly burrs on the machined surface, called scales. thorn. The appearance of scales significantly increases the surface roughness of the machined surface.

2.Residual area: The residual area is the area of the machined surface that has not been cut off after being cut by the main and auxiliary cutting edges.

3.Vibration: During the cutting process, due to the periodic vibration of the process system, streaks or ripple marks appear on the machined surface, and the surface roughness value is significantly increased.

4.built-up edge: in the cutting process, when the built-up edge, its protruding part can be cut into the workpiece instead of the cutting edge, draw a groove on the machined surface; when the built-up edge falls off, Part of the built-up edge fragments adhere to the machined surface, forming fine burrs, resulting in increased surface roughness.

Second: What are the factors that affect the surface roughness?

In fact, all factors affecting scales, residual area, and vibration built-up edge will affect the surface roughness of the machined surface.

1.cutting amount: the amount of feed has the greatest impact on the residual area. The feed rate is reduced and the residual area is reduced.

When cutting plastic metal, when the cutting speed is very low or high, the surface roughness value is small. This is because the built-up edge is not easy to occur at low speeds; when the cutting speed is high, the plastic deformation is reduced, and the occurrence of scales can be eliminated. When cutting brittle materials, the influence of the cutting speed is small, because the material deformation is small, so the surface roughness value is also reduced.

2.Tool material: The tool material is different, the radius of the edge arc and the time to keep sharp are different. High-speed steel tools can be sharpened sharply, but with a short hold time, so the surface roughness is small at low speed cutting. After the carbide tool is sharpened, the radius of the cutting edge is large, and the cutting surface roughness value is small at high speed.

3.tool geometry parameters: the tool tip arc radius, lead angle and secondary declination have a greater impact on the residual area and vibration. Generally, when the radius of the tool nose increases, the surface roughness value is small, but if the machine tool stiffness is low, the radius of the tool nose arc is too large or the lead angle is too small, due to the cutting force. The vibration is increased to increase the surface roughness value.

4.Workpiece material: When processing plastic material, the lower the plasticity of the workpiece material, the higher the hardness, the less the phenomenon of built-up edge, scale and chill, and the smaller the surface roughness value. Therefore, the surface roughness value of high carbon steel, medium carbon steel and quenched and tempered steel after processing is smaller than that of low carbon steel. When the cast iron is processed, the surface roughness value ratio of the cast iron is the same under the same processing conditions. Steel is big.

In summary, the scales, residual area, and vibration built-up edge will affect the surface roughness of the machine. We should improve and pay attention to the amount of cutting, tool material, tool geometry and material of the workpiece.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off