Various types of medical equipment parts machining case studies - PTJ Shop

Various types of medical equipment parts

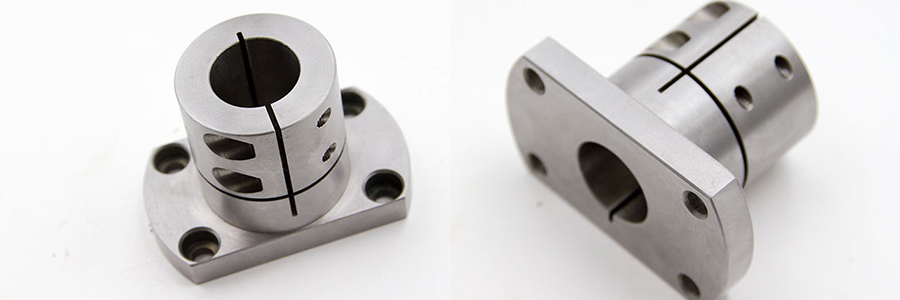

| Coupling component refers to a device that connects two shafts or shafts and rotating parts, rotates together during transmission and power, and does not disengage under normal conditions. Coupling parts can be machined from a variety of metal materials. |

The illustration coupling parts are made of stainless steel 316 material. 316 stainless steel has high corrosion resistance, atmospheric corrosion resistance and high temperature resistance, and work hardenability is good. After CNC precision CNC lathe processing, drilling, wire cutting, surface treatment and other processing techniques, and after three-point testing to meet the technical requirements, it is sent to the customer for assembly, and maintains technical support for customer parts during the operation of the equipment.

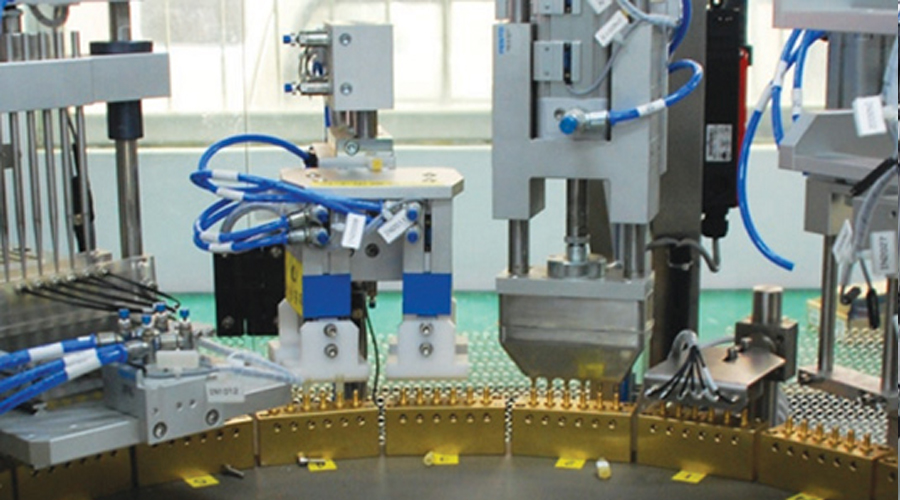

PTJ Shop has many years of processing history of various types of couplings, with rich experience, and has the advantages and advantages of research and development of high-tech products and mass production, which can meet the various needs of users. For all kinds of medical equipment and parts processing, look for PTJ Manufacturing Shop.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about Cnc Machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off