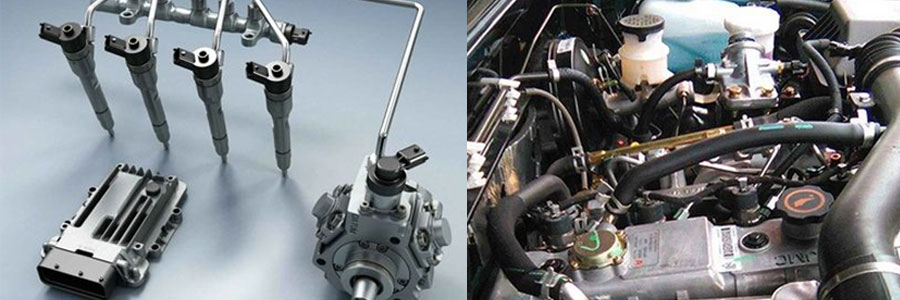

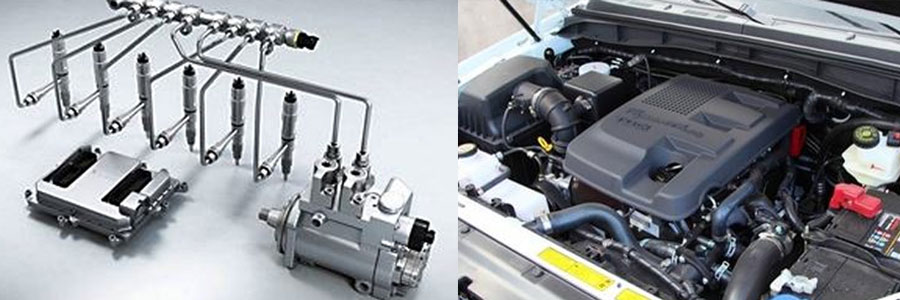

Custom automotive high pressure common rail parts case studies

Custom automotive high pressure common rail parts

| PTJ Shop focuses on automotive high-pressure common rail parts for ten years, supplying the most complete engine parts, main products or services: metal guide paper shaft processing; metal paper guide shaft processing; CNC lathe parts processing; precision lathe parts processing; CNC lathe parts processing Precision stamping parts processing; metal stamping parts processing; stainless steel stamping parts processing; flat copper tube processing; hollow tube processing; brass tube processing. Welcome to consult. |

Basic Information:

- Name: Automotive high pressure common rail parts

- Stamping type: hardware

- Processing size: can be customized

- Precision punching method: open type

- Applicable models: all

- Weight: Customizable

- Model: various models

- Processing cycle: 4-7 days

- Proofing cycle: 1-3 days

- Material: carbon steel

- Mold: multi-process continuous mode

- Tolerance: 0.05

- Category: A column

- Surface treatment: electroplating, oxidation, blackening, spraying

-

Process: cutting, punching, blanking, trimming, bending

Features:

- Double motor Panasonic double frequency conversion, computer PLC control, bag length is set to cut, no need to adjust empty, one step in place, save time and film.

- Button-type man-machine interface, full Chinese / English menu, parameter settings are convenient and fast.

- Fault self-diagnosis function, the fault is clear at a glance.

- High-sensitivity photoelectric eye color tracking, so that the sealing and cutting position is more accurate.

- Temperature independent PID control, better suited to a variety of material envelope.

- Positioning stop function, no sticking knife, no film.

- The transmission system is simple, reliable, and convenient to maintain.

-

All control is realized by software, which is convenient for function adjustment and technology upgrade.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about Cnc Machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off