How to weld sheet metal - PTJ Manufacturing Shop

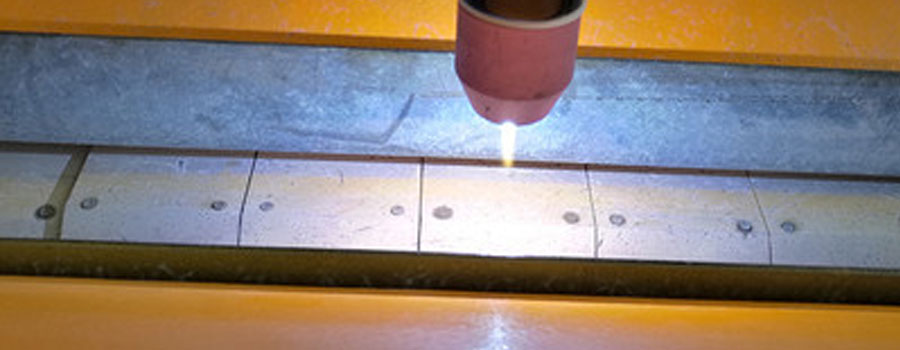

Weld sheet metal methods

At present, most of the metals can be welded by one or more welding methods.The weldability of the metal can be welded in a wide range of thicknesses, from the thinnest plate to the thickest plate.

Moreover, such metals can be welded at any location; some metals cannot be joined by any soldering method.

The properties of various metal materials (such as melting point, density, thermal conductivity, tensile strength and plasticity) can be used to measure the ease of welding of metal materials.

Several materials suitable for welding metal sheets

Among all metal materials, ordinary carbon steel is the most widely used and the largest amount;

Followed by cast iron, but most of the cast iron material is not used for welding structures, but also needs welding or welding;Furthermore, alloy steel, different alloy steels (such as low alloy high strength steel, heat treated steel, ultra high strength steel, etc.) need to be welded by different welding processes;

Aluminum and its alloys are used in a wide range of applications due to their large reserves. Especially for applications requiring light weight, different aluminum alloys have different properties and require different welding processes for welding.

Copper and its alloys are mainly used in applications where electrical conductivity, corrosion resistance or thermal conductivity is required;

The welding process of stainless steel and cast steel is similar to the rolling steel with the same composition. The performance of different stainless steels is quite different, and the welding process is different;

Nickel and its alloys, although not widely used and used in small amounts, are important because nickel alloys are the best choice for certain applications;

Magnesium and its alloys are the least used of the commonly used metals. She is also important because it is the lightest of the commonly used metals. Most of this material is used in welded structures.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off