What is oem parts in cnc machining area - PTJ Manufacturing Shop

OEM parts meanings

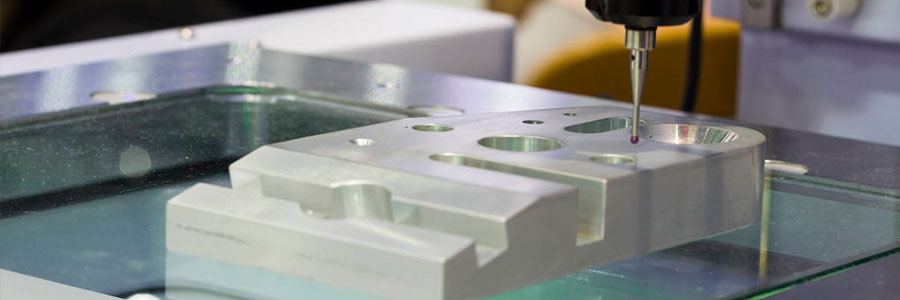

The OEM parts are aluminum parts, copper parts or iron parts produced by the CNC processing factory according to the drawings and requirements of the customers. The process includes cnc turning, milling and so on.

Custom overview

OEM parts are also known as custom metal parts, according to customer's drawings and requirements for the production of aluminum parts, copper parts, stainless steel parts, magnesium parts, titanium parts, iron parts and so on. In China, many CNC processing plants offer OEM metal parts to overseas companies, such as PTJ CNC processing plants. With 50 precision CNC machines and 150 employees, it is very suitable for providing OEM services to customers.

Customization process

First, the detailed drawings and all the requirements sent by the customer, and remind the CNC processing manufacturers or suppliers of the key technical requirements, including: unit weight (machining or rough), dimensional tolerances of non-standard parts and finished part weight (machined or Rough), requirements for materials such as strength and hardness, surface finish requirements, and special heat treatment requirements.

Second, the factors of price volatility. The price of OEM metal parts is mainly affected by the price and exchange rate of metal materials. Normally, if the exchange rate fluctuates by more than 3%, the CNC processing plant will require a price adjustment. If the metal material price fluctuates beyond a certain range, the CNC processing plant also needs to adjust the price. Of course, if the price of metal materials has been greatly reduced or the exchange rate has increased, buyers must also reduce the price of castings with suppliers.

<hr />

<span>

<table style="width:100%;" cellspacing="0" cellpadding="2" bordercolor="#000000" border="1">

<tbody>

<tr>

<td style="background-color:#009900;vertical-align:middle;border-width:1px;border-style:solid;border-color:#FFFFFF;">

<p>

<strong><span style="color:#FFFFFF;font-size:14px;">PTJ Machining Capabilities</span></strong>

</p>

</td>

</tr>

<tr>

<td style="background-color:#CCCCCC;border-width:1px;border-style:solid;border-color:#009900;">

<strong><span style="color:#337FE5;">Automatic Bar Machining</span></strong> <span style="color:#666666;">– <span style="color:#333333;">Multi-spindle cam automatic screw machines</span></span><br />

<span style="color:#337FE5;"><strong>CNC Turning </strong></span><span style="color:#333333;">– CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components</span><br />

<span style="color:#337FE5;"><strong>Custom Machining</strong></span> <span style="color:#333333;">- with up to 12 axes of control</span><br />

<span style="color:#337FE5;"><strong> Multi Spindle Machining</strong></span><span style="color:#333333;">- ISO 9001:2015 certified</span><br />

<span style="color:#337FE5;"><strong>Screw Machine Products</strong></span><span style="color:#333333;"> – The number of customized production parts per hour can reach 10000pcs</span><br />

<strong><span style="color:#337FE5;">Swiss Machining </span></strong><span style="color:#333333;">– with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation</span><br />

<span style="color:#009900;"><strong><span style="color:#337FE5;">High Volume Machining</span><span style="color:#333333;"> </span></strong></span><span style="color:#333333;">– 100 Advanced Production Turning Bar Automatics On-line and Ready</span><br />

<span style="color:#337FE5;"><strong>CNC Milling</strong></span><span style="color:#333333;"> - Machining Fully compliant with the exacting requirements of our customers</span><br />

<span style="color:#337FE5;"><strong>5 axis (11 axis) Machining</strong></span><span style="color:#333333;"> – Tolerance | 0.1mm alignment</span>

</td>

</tr>

</tbody>

</table>

</span>

<p>

What Can we help you do next?

</p>

<p>

∇ Get more information about <strong><a href="https://www.ptjmachining.com/machining-manufacturer.html">cnc machining Shop</a></strong>

</p>

<div>

<p>

→<a href="https://www.ptjmachining.com/cnc-parts.html">Case study</a>-Find out what we have done.

</p>

<p>

→Ralated tips about <a href="https://www.ptjmachining.com/cnc-machining-services.html">cnc machining services</a>

</p>

</div>

<hr />

By <a href="https://www.ptjmachining.com" title="Posts by ptjcnc" rel="author">PTJ Manufacturing Shop</a>|Categories: <a href="https://www.ptjmachining.com/" rel="category tag">Blog</a>|Tags: <a href="https://www.ptjmachining.com/cnc-milling-services.html" rel="tag">cnc milling services</a>, <a href="https://www.ptjmachining.com/cnc-turning-services.html" rel="tag">cnc turning services</a>, <a href="https://www.ptjmachining.com/milling-parts.html" rel="tag">milling parts</a>, <a href="https://www.ptjmachining.com/turning-parts.html" rel="tag">turning parts</a>, <a href="https://www.ptjmachining.com/machining-parts.html" rel="tag">machining parts</a>, <a href="https://www.ptjmachining.com/special-parts.html" rel="tag">special parts</a>,<a href="https://www.ptjmachining.com/FAQS.html">faqs</a>,<a href="https://www.ptjmachining.com/technical-news.html">technical news</a>,<a href="https://www.ptjmachining.com/company-news.html">company news</a>,<a href="https://www.ptjmachining.com/material-news.html">material news</a> |Comments Off

<hr />