What is precision machining- PTJ Manufacturing Shop

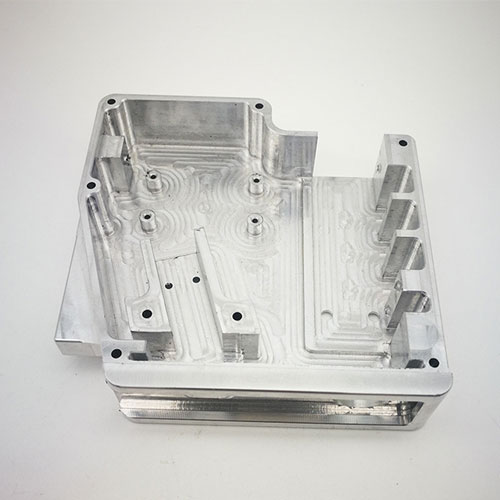

The precision of modern precision machining and its surface finish are higher than traditional processing methods.Read about what the precision service and etc.Precision machining processes include precision miiling and cutting (such as diamond boring, precision turning, wide-blade fine grazing, etc.) and high-gloss and high-precision grinding. Precision machining precision is generally 10~0.1μm, tolerance class is above IT5, and surface roughness Ra is below 0.1μm.

|

Precision machining is the process of cutting a very thin layer of metal on the surface of a workpiece with a high or low cutting speed, a very low cutting depth and a feed with high precision and rigidity. Obviously, this process can significantly improve the machining accuracy of the part. Since the residual area of the cutting process is small, and the adverse effects of cutting force, cutting heat and vibration are eliminated to the utmost extent, the surface deterioration layer left by the previous process can be effectively removed, and the surface after processing is basically free of residual pull. The stress and roughness are also greatly reduced, which greatly improves the quality of the machined surface. We have over 10 years’ experience in die casting and cnc machining, and we can guarantee you of high-quality parts. We will be your partner for all your machining, casting and finishing requirements. Get in touch with use to discuss your needs. |

High-precision grinding also requires high precision and rigidity of the machine. The grinding process uses a finely-trimmed grinding wheel to produce multiple contoured micro-cutting edges on each abrasive grain with a small grinding depth. Under proper grinding pressure, the fine chips are cut from the surface of the workpiece plus the sliding of the micro-cutting edge in the micro-cutter state, the pressing and smoothing action and the friction polishing effect of the multiple feed-free grinding stage. In order to obtain a high-gloss surface with high processing precision and good physical and mechanical properties. In summary, the precision machining process can improve the machining accuracy and surface quality of the workpiece.

|

Milling Processes |

Boring Counterboring Countersinking Drilling Pocheting |

Profiling Reaming Tapping Threading |

|

Materials |

Alloy Steels Aluminum Bar Stock Brass |

Bronze Cst Iron Stainless Steel Steel Forgings |

|

Equipment Used |

CNC Vertical Machining Centers CNC Horizontal Machining Centers |

|

|

Machinery Axes |

4 | |

|

Length |

Up to 72 in |

|

|

Width |

Up to 30 in |

|

|

Height |

Up to 30 in |

|

|

Tolerances |

±0.0002in |

|

|

Production Volume |

Prototype Medium Volume High Volume |

At present, the application of precision and ultra-precision technology in China is no longer limited to a few sectors such as defense defense and aerospace. It has expanded to many areas of the national economy, and its application scale has also increased significantly. Computers, modern communications, film and television communications and other industries now require sophisticated, ultra-precision processing equipment as a supporting condition for their rapid development. Precision and ultra-precision machining of computer disks, video recorder heads, multi-face prisms for laser printers, photoconductors for copiers, etc., are all efficient and high-volume automated production methods.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about Cnc Machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off