What material is used for 3d printing? - PTJ Manufacturing Shop

The status quo of the 3D printing market

At present, most of the domestic 3D printing is used in the prototype industry, that is, proofing. However, with the advancement of technology and the abundance of materials, there are more and more companies that use 3D printing to manufacture functional products and small batch production.

Type of 3D printed material

So the main thing here is non-metallic materials.

3D printing is really suitable for proofing and making a hand.

This is closely related to the technology of 3D printing itself. It has its own differentiated manufacturing, on-demand production, low modification cost, low proofing cost, and no need to open the mold. In the field of hand verification, almost no technology is comparable to 3D printing technology.

The printing technology of 3D printed non-metallic materials mainly includes FDM, SLA, SLS, MJF technology, and materials can be classified into three types according to the simple shape.

1: Wire Suitable for FDM 3D printing, there are many types of materials, but the accuracy is slightly worse, and post-processing to support trouble. Home 3D printers generally choose FDM, but there are also many excellent industrial FDM printers.

2: Liquid photosensitive resin Suitable for SLA 3D printing, the material type is small, the molding surface is smooth, and the paint can be sprayed after polishing. The performance of the product changes with time and environment, which is not suitable for practical industrial applications, and is more suitable for the appearance verification of the product.

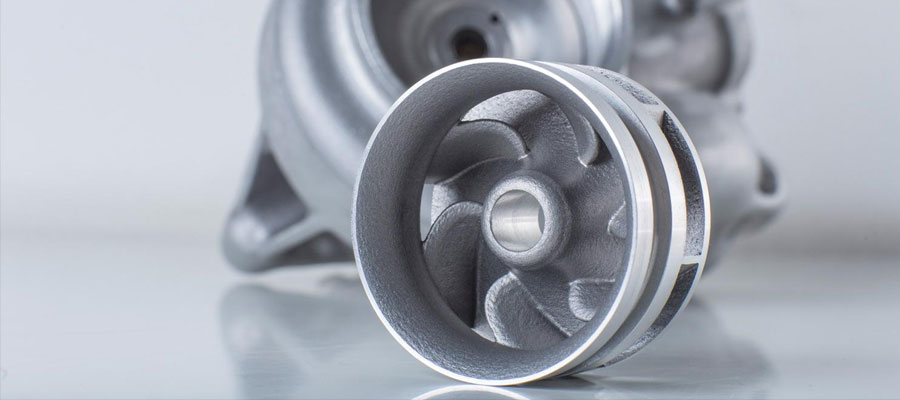

3: Powder material nylon Suitable for SLS and MJF 3D printing technology, the material type is small, the surface will have graininess, but the product has the advantages of high temperature resistance and good toughness, and is suitable for the manufacture of functional parts. It can be used for proofing or small batch production and can be used in actual industrial production.

Because we don't have FDM equipment in our PTJ factory, we don't have much say, so we won't say much. From the perspective of our existing materials, SLA is more popular, because the material price is low, the printed product is relatively smooth, and it is not troublesome to post-process. It can also carry out subsequent painting operations, and the finished product is very good. Suitable for crafts and surface products. However, the PTJ factory is more optimistic about nylon powder materials because its printed products are stronger than resin products in terms of toughness, strength and high temperature resistance. It has advantages in widening 3D printing applications. After better optimization of accuracy and production efficiency, it is easier to form stable orders for small batch or medium batch customization later.

However, the PTJ factory is more optimistic about nylon powder materials because its printed products are stronger than resin products in terms of toughness, strength and high temperature resistance. It has advantages in widening 3D printing applications. After better optimization of accuracy and production efficiency, it is easier to form stable orders for small batch or medium batch customization later. But in any case, the material and personnel costs are a hurdle that cannot be crossed. Regardless of any company, the company is profitable, and only if it produces benefits, can the company operate better. Continue to introduce more advanced technology, high-quality materials, high-precision equipment, and continue to provide users with better service, which is the foundation of enterprise development. There are two reasons why users choose to supply a company.

But in any case, the material and personnel costs are a hurdle that cannot be crossed. Regardless of any company, the company is profitable, and only if it produces benefits, can the company operate better. Continue to introduce more advanced technology, high-quality materials, high-precision equipment, and continue to provide users with better service, which is the foundation of enterprise development. There are two reasons why users choose to supply a company.

- Let customers enjoy the same quality service at a lower cost.

-

Allow customers to enjoy higher levels of service at the same cost.

PTJ, who has been cultivating the prototype industry for 5 years, knows that the price of powder materials has been high. Although there is a wide range of application markets, it is also very popular with users and has received a lot of praise. But it is not a small batch of orders. The fundamental point is that the cost of powder materials is too high to reach the mass production level, and many SMEs can't stand it.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off