What are the machining requirements for round tube CNC lathe machining?- PTJ Manufacturing Shop

In the past, many people were not very clear about their processes for product manufacturing. They mainly talked about various aspects of CNC lathe processing. I believe that after understanding this type, you can better understand the current market conditions and their usual time. What are the work done?

In fact, if you want to make a product, you need to pay attention to a lot of things. For example, when drawing a drawing, you must determine it according to the actual size. Otherwise, errors may occur after the production is completed, so the product produced cannot be produced. When used, it will produce more losses, so the requirements for round tube CNC lathe processing must be achieved. Otherwise the consequences cannot be borne.

In addition, it is necessary to make corresponding production steps according to the shape of the products to be produced. Only by selecting the appropriate production method can the product be protected from damage and better put into use, so it is necessary to pay attention to this aspect in the production. an examination.

If you feel that you don't know much about the manufacturing requirements of various products and want to make new products better, then you can go to PTJ Manufacturing shop, where you can learn more new production methods and help you better. The production of new types of products, can also let them know more about the knowledge that is not usually understood, and better engage in this production work.

|

PTJ Machining Capabilities |

|

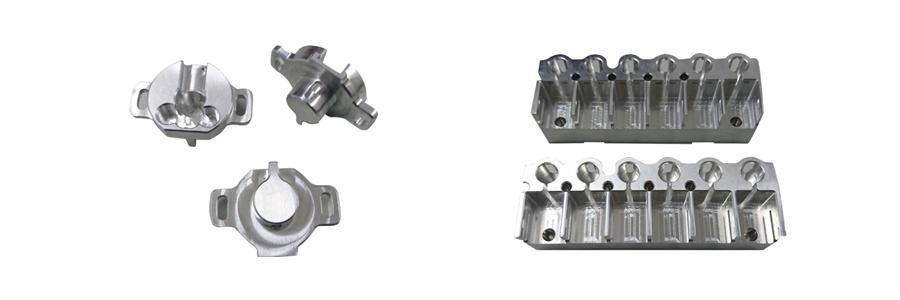

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off