What is superalloy?

What is superalloy?

|

High-temperature alloy refers to a class of metal materials based on iron, nickel and cobalt that can work for a long time under high temperature above 600 ℃ and certain stress; |

And has a high temperature strength, good oxidation and corrosion resistance, good fatigue performance, fracture toughness and other comprehensive properties.

And has a high temperature strength, good oxidation and corrosion resistance, good fatigue performance, fracture toughness and other comprehensive properties.

The superalloy is a single austenite structure, which has good structural stability and reliability at various temperatures.

Based on the above performance characteristics, and the high degree of alloying of high-temperature alloys, it is also called "superalloy" and is an important material widely used in aviation, aerospace, petroleum, chemical industry, and ships. According to the matrix element, superalloys are divided into iron-based, nickel-based, cobalt-based and other superalloys (inconel / monel / hastelloy / nitronic-60 etc).

The service temperature of iron-based superalloys can generally only reach 750 ~ 780 ℃. For heat-resistant parts used at higher temperatures, nickel-based and refractory metal-based alloys are used. Nickel-based superalloy occupies a particularly important position in the entire superalloy field. It is widely used to manufacture the hottest end parts of aviation jet engines and various industrial gas turbines.

|

PTJ Machining Capabilities |

|

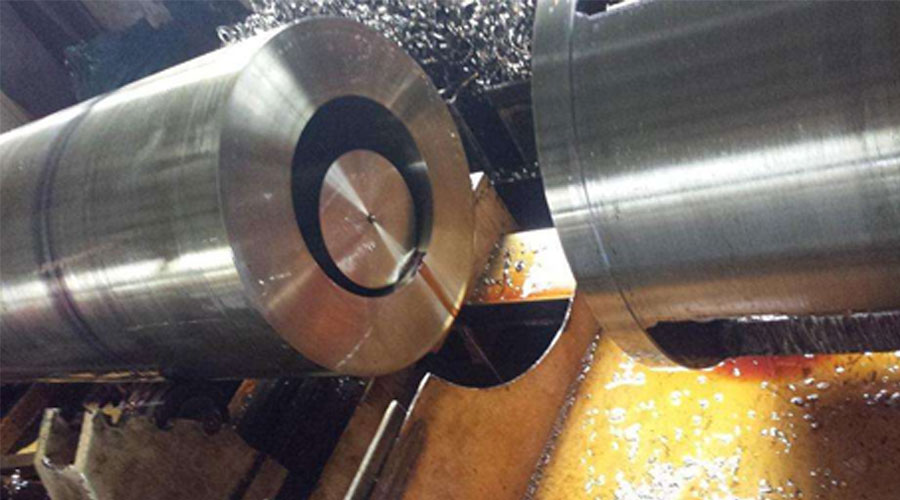

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off