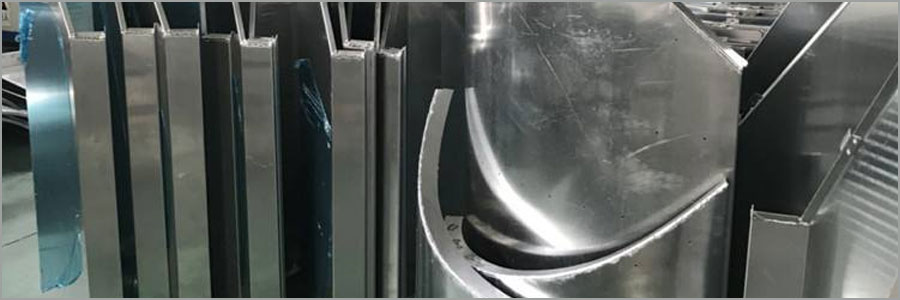

Impure material can affect the quality of cnc machining aluminum parts

Affect the quality of cnc machining aluminum parts

| We all know that the main element of aluminum profiles is aluminum, while adding other metals or non-metal elements, such as magnesium, manganese, copper, silicon, zinc, etc., an alloy formed by heating, extrusion, surface, etc. According to the different alloying elements, the grades of aluminum profiles are different, and the industries corresponding to each grade are also different, for example, some are used exclusively in the automotive field, and some are used exclusively for aerospace; |

The main alloying elements commonly found in aluminum profiles are magnesium, copper, silicon, zinc and manganese. The secondary elements are chromium, nickel, lithium, iron, titanium, and some impurity elements such as vanadium, niobium, calcium, lead and antimony. , tin, antimony, sodium, etc., although the content of these impurity elements is generally very low, but it will have some impact on the quality of aluminum profiles;

The main alloying elements commonly found in aluminum profiles are magnesium, copper, silicon, zinc and manganese. The secondary elements are chromium, nickel, lithium, iron, titanium, and some impurity elements such as vanadium, niobium, calcium, lead and antimony. , tin, antimony, sodium, etc., although the content of these impurity elements is generally very low, but it will have some impact on the quality of aluminum profiles;

The first is calcium. Calcium can form CaSi with silicon. It has a certain effect on the conductivity of pure aluminum. Calcium and aluminum form a calcium aluminophosphate compound. It is insoluble in aluminum and can change the cutting performance of aluminum alloy. The calcium disilicide cannot heat-treat the aluminum profile, and a small amount of calcium can remove hydrogen from the aluminum liquid, which can reduce the mechanical properties of the aluminum profile.

Then talk about the metal element vanadium, vanadium in the aluminum alloy will form a compound called VAL11, in the process of casting can play the role of refining the grain, can also play a role in recrystallizing the recrystallized structure It can also increase its crystallization temperature, but it is very difficult to melt, and the refining effect is not as good as titanium and zirconium. Adding a small amount of vanadium can make the surface of the aluminum profile smoother.

The second is sodium. The melting point of sodium is very low. It is almost insoluble in aluminum. When the aluminum profile containing sodium is heated by melting and casting, the sodium solidified on the grain boundary can form a liquid adsorption layer, causing brittle cracking to form NaClSi. When there is no free sodium in the compound, when the content of magnesium is more than 2%, free sodium is precipitated to produce sodium brittleness. Therefore, the sodium salt solvent is not allowed in the high magnesium aluminum alloy profile, but strontium may be added to prevent sodium brittleness. Chlorination can also be used to prevent sodium brittleness, so that sodium chloride can be discharged. The addition of niobium to the aluminum-magnesium alloy can form disodium telluride into the base layer of the metal, and the sodium element can reduce the load-bearing capacity of the aluminum profile. The effect of use is reduced.

Once again, it is a bismuth element. It is mainly used as a modifier in cast aluminum alloys. It is rarely used in deformed aluminum alloys. It is only used in aluminum-magnesium deformed aluminum alloys. The purpose is to prevent sodium brittle cracking instead of hydrazine. The addition of antimony in some aluminum-magnesium-zinc-copper alloys can improve the process properties of hot and cold pressing and improve the mechanical properties of aluminum profiles.

There are also strontium elements, which are toxic and can cause allergic poisoning. Therefore, it is important to remember that aluminum profiles used in the production of foods and beverages should not contain strontium, which is beneficial to food safety and personal safety. The bismuth element can effectively improve the structure of the oxide film layer and reduce the burning loss and inclusion during the casting, and the aluminum profile used for the welding substrate should have the strontium content below 8 μm/ml.

Finally, lead, tin and antimony elements have very low melting points and low solid solubility in aluminum, which can reduce the strength and cutting performance of aluminum profiles, and have a certain influence on the mechanical properties and load-carrying capacity of aluminum profiles. The lanthanum element will expand when solidified, and has a certain feeding effect on the forming of the aluminum profile. The addition of yttrium to the aluminum-magnesium alloy can also prevent the sodium from brittle cracking, and is suitable for use in deformed aluminum alloy.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about Cnc Machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off