Manufacturers share cnc turning worm gear shaft program

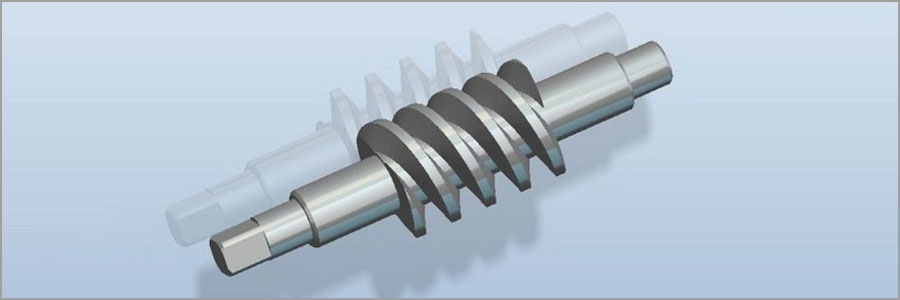

Machining worm gear shaft

| Guangzhou CNC and Dalian machine tools and Shenyang machine tools should be the common CNC machine tools in the school. Today, we have compiled a program for machining worms and trapezoidal threads. If you have used macro programs, and this program is not very If you are familiar with it, you can apply this program directly. |

First of all: worm and large pitch trapezoidal thread features and processing methods

First of all: worm and large pitch trapezoidal thread features and processing methods

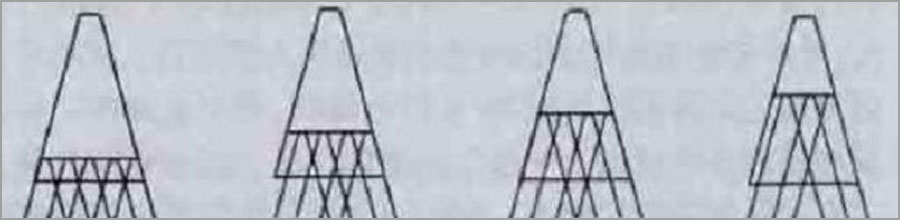

CNC lathe machining worm and large lead thread, no matter the oblique or left and right cutting method, the cutting resistance is very large. Previously, only high-speed steel turning tools were used for low-speed turning, and the production efficiency was very low. Although it can be machined with cemented carbide tools, it is necessary to try to reduce the cutting depth of the cutting edge. Therefore, this paper uses the method of "layered cutting" to process.

The socket of the thread or the worm is divided into several layers and converted into a plurality of shallow trapezoidal grooves for cutting. Each layer of cutting adopts a first straight-to-left-to-left turning method. Since the groove depth does not change during the left cutting, the tool only needs to do the left direction! In the direction of the guide rail, the feed is combined, so that the left and right cutting method and the oblique step method are organically combined. Since only one cutting edge is used for cutting, the cutting allowance can be effectively controlled, which can ensure the surface quality and the tool well. The service life.

Macro, machining worm and trapezoidal thread macro program

1、the choice of tools; because SMEs buy more economical CNC lathes, the common domestic machine is Guangzhou CNC and Huazhong CNC, so this article uses a wide number of 980TD as an example to program processing. The turning tool uses a carbide turning tool (the width of the cutting head is slightly smaller than the width of the bottom of the trapezoidal thread).

2、processing macro program; such as processing Tr40 × 10-7e trapezoidal thread (the program is as follows; O001! program name,

T0101M03S350;! Select the thread turning tool (set the spindle speed to 350 rpm, G99G21G97M08; (feed per revolution (open cutting fluid)

G65H01P#101Q10; (pitch 10mm)

G65H01P#102Q5.25; (tooth height 5.25mm)

G65H01P#103Q0; (initialize each Z-direction offset)

G65H01P#104Q0.2; (each X feed)

G65H01P#105Q15; (every Z direction starting point)

G65H01P#106Q-30; (Trapezoidal thread length 30mm)

G65H01P#107Q40; (nominal diameter of thread)

G65H01P#130Q3.5; (thread head width 3.5mm)

G65H01P#131Q3.928; (thread groove bottom width 3.928mm)

G65H03P#132Q#131R#130; (thread groove bottom width minus cutter head width)

G65H02P#108Q#107R3; (offset nominal diameter 3mm, if it is machined internal thread, change to H03)

G00X#108; (X-direction starting point)

N100G65H03P#120Q#105R#103; (calculate Z-direction starting point)

G00Z#120; (Z-direction starting point)

G65H03P#109Q#107R#104; (feed depth in X direction)

G92X#109Z#106F#101; (Trapezoidal thread processing)

G65H03P#103Q#103R0.2; (Z-direction offset is reduced by 0.2mm each time)

G65H03P#110Q#102R#104;G65H33P#111Q2R15;! Tangent value calculation (if it is a worm, R20, G65H04P#121Q#111R#110; G65H02P#133Q#112R#132; (Z-direction movement per layer)

G65H86P100Q-#103R#133; (If each layer is not cut (return N100, pay attention to the negative sign)

G65H02P#104Q#104R0.2;

G65H04P#114Q#102R2;

G65H03P#116Q#107R#114; (X-direction movement per layer)

G65H01P#103Q0; (each layer is cut back to the initial value of Z direction)

G92X#109Z#106F#101; (finishing the first knife on the right side)

G92X#109Z#106F#101; (finishing the second knife on the right side)

G92X#109Z#106F#101; (finishing the third knife on the right side)

G65H03P#134Q#105R#132; (finishing the left side of the starting point calculation)

G00Z#134;! Finishing the left side Z-direction

G92X#109Z#106F#101;! Finishing the first knife on the left side

G00Z#134;

G92X#109Z#106F#101;! Finishing the second knife on the left side

G00Z#134;

G92X#109Z#106F#101;! Finishing the third knife on the left side

G00X100Z100M09;! Keep away from the workpiece (close the cutting fluid

M05;! Spindle stop

M30,! End of program

Then: how to use

Input the above program into the machine tool to save it. If you encounter trapezoidal thread or worm in the process, some main parameters will be modified in the program. The parameters are mainly large diameter, pitch, tooth depth, groove width, and tool. The tool number and the cutter head width (the modified position is described in the brackets in the program. After the check is correct, it can be processed, which is very convenient and does not require the operator to have high macro editing ability.

Practice has proved that the use of "layered cutting" method for machining worm and trapezoidal thread can complete the machining of worm and large pitch thread with high precision and high efficiency without ensuring that the tool is not knives or knives.

PTJ Manufacturing Shop is a professional manufacturer specializing in high-quality precision parts customization and mass production. The company has successfully passed ISO9001, ISO14001, IATF16949 and other quality management certifications as well as high-tech enterprise audits. The product coverage is wide and the processing precision can be controlled. 0.01mm is one of the few manufacturers in Dongguan that has the qualification for auto parts processing.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off