Materials used in the machining of precision parts for valves and main accessories

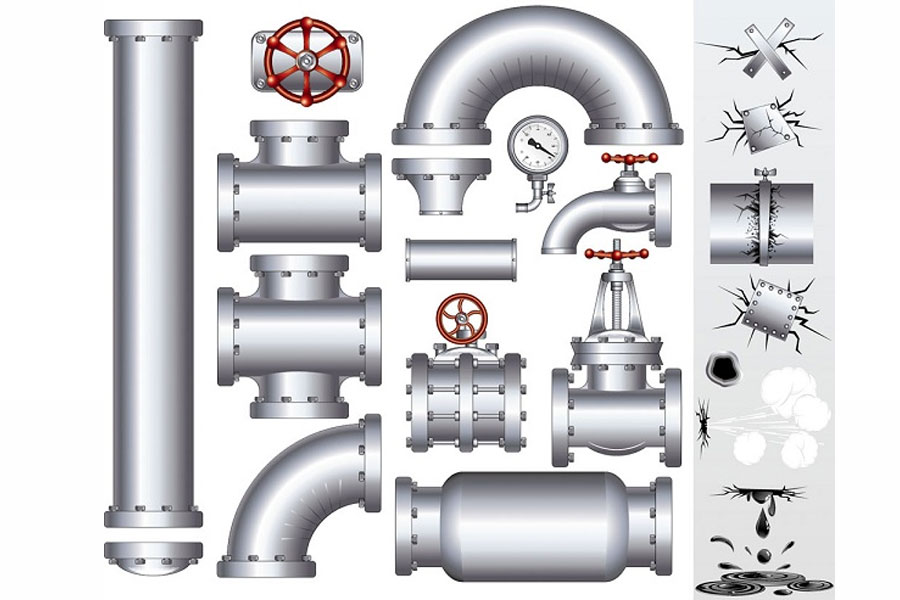

What are the main precision parts and processing materials of the valve?

| First of all, there are many parts and materials for processing valves, including many kinds of copper and alloy materials. The material selection factors of valve manufacturing parts are mainly the following. |

- It can meet the pressure temperature and characteristics of the working medium;

- Its parts can play a role in the valve structure under the force state;

- It has better processability;

- Its material costs can not be too high;

Valve precision parts

It mainly includes the following:

- Executing agency: 1. Start the actuator; 2. Hydraulic actuator; 3. Electric actuator; 4. Electro-hydraulic actuator; 5. Start the actuator; 6. Manual actuator;

- Positioner and accessories: 1.limit switch; 2.retaining valve; 3.filter pressure reducing valve; 4.servo amplifier; 5.intelligent valve positioner; 6.electric valve positioner; 7.pneumatic valve positioner; 8.electro-hydraulic servo; 9.Electrical converter; 10.valve position transmitter; 11.solenoid valve; 12.pneumatic amplifier; 13.electro-hydraulic servo; 14.intelligent module; 15.servo amplifier; 16.alarm; 17.explosion-proof coil;

- Test equipment and other valve accessories: 1, valve testing machine; 2, handle; 3, hand wheel; 4 worm wheel; 5, valve body; 6, valve core; 7, valve stem; 8, valve cover; 9, valve silencer 10, signal generator; 11, blank; 12, mold; 13, bolt and nut; 14, clamp; 15, spring; 16, diaphragm; 17, packing; 18, packing; 19, O-ring; , flow juice; 21, PTFE products; 22, gasket; 23, flange; 24, elbow; 25, quick joint; 26, retractor; 27, flow meter; 28, filter; Standard solid parts; 30, machine marking machine; 31, actuator; 32, valve positioner; 33, pipeline;

-

Valve part material:There are many materials used in the manufacture of valves. Different grades of ferrous metals, non-ferrous metals, alloys and non-abbreviated materials. The valve body and the material of the valve cover and valve plate are the main materials of the valve precision parts. They directly withstand the medium pressure and the materials used. Must meet the "pressure and temperature rating of the valve" regulations, the following commonly used materials:

1. Gray cast iron: Gray cast iron is suitable for water, steam, air, gas and oil medium with nominal pressure PN≤1.0MPa, temperature of -10°C~200°C. The grades frequently used for gray cast iron are: HT200, HT250, HT300, HT350;

2, malleable cast iron: for nominal pressure PN ≤ 2.5MPa, temperature -30 ° C ~ 300 ° C water, steam, air and oil media, often used material grades are: KTH300-06, KTH330-08, KTH350 -10;

3, ductile iron: suitable for nominal pressure PN ≤ 4.0MPa, temperature -30 ~ 350 ° C water, steam, air and oil and other media, common material grades are: QT400-15, QT450-10, QT500- 7. In view of the current domestic process level, each manufacturer's differentiation is different, users often do not get the test results. According to past experience, it is recommended to choose PN≤2.5MPa, and it is safer to use steel valves for valves.

4. Acid-resistant high-silica ductile iron: suitable for corrosive media with nominal pressure PN≤0.25MPa and temperature below 120°C;

5. Carbon steel: suitable for water, steam, air, hydrogen, ammonia, nitrogen and petroleum products with nominal pressure PN≤32Mpa and temperature -30~425°C. Commonly used grades are WC1, WCB, ZG25 and high quality steel 20, 25, 30 and low alloy structure 16Mn.

6. Copper alloy: It is suitable for water, seawater, oxygen, air, oil and other media with nominal pressure PN≤2.5MPa, and steam medium with temperature of -40~250°C. The commonly used grades are ZGnSn10Zn2 (tin bronze). H62, Hpb59-1 (brass), QAZ19-2, QA19-4 (aluminum bronze);

7. High-temperature steel: suitable for steam and oil products with nominal pressure PN≤17.0MPa and temperature ≤570°C. Commonly used grades are ZGCr5Mo, 1Cr5M0. ZG20CrMoV, ZG15Gr1Mo1V, 12CrMoV, WC6, WC9, etc. The specific selection must be in accordance with the valve. Pressure and temperature range regulations;

8, low temperature steel, suitable for nominal pressure PN ≤ 6.4MPa, temperature ≥ -196 ° C ethylene, propylene, liquid natural gas, (^-^) V nitrogen and other media, commonly used brands are ZG1Cr18Ni9, 0Cr18Ni9, 1Cr18Ni9Ti, ZGOCR18Ni9;

9. Stainless acid-resistant steel: suitable for medium pressure PN≤6.4MPa, temperature ≤200°C medium such as nitric acid and acetic acid. Commonly used materials are ZG0CR18NI9TI, ZGOCR18NI10 (nitrate resistant), ZGOCR18NI12MO2TI, ZG1CR18NI12Mo2Ti (acid and urea);

Sealing surface material

The sealing surface is a very important working surface of the valve. The quality of the sealing surface is directly related to the service life of the valve. Generally, the main considerations of the sealing surface material are corrosion resistance, scratch resistance, erosion resistance, oxidation resistance, etc. There are two categories of materials:

- Soft materials:rubber, mainly containing nitrile rubber, fluorine rubber, etc;plastic, PTFE, nylon and other materials;

-

hard materials:Copper alloy for mortgage valves;chrome stainless steel, for ordinary high and medium pressure valves;Stellite alloy, used for high temperature and high pressure valves and strong corrosion valves;Nickel-based alloys for corrosive media;

Stem material

The valve stem is subjected to tension, pressure and torsion during the opening and closing of the valve, and is directly based on the medium, and there is relative frictional movement between the valve and the filler. Therefore, the stem material must be sufficient downstream at the specified temperature. The strength and impact toughness, certain corrosion resistance and scratch resistance, and good processability. The commonly used valve stem materials are as follows:

1. Carbon steel

When used for water and steam medium with low pressure and medium temperature ≤300 °C, A5 ordinary carbon steel is generally used;

For medium and medium temperature and medium temperature ≤ 450 ° C water, steam medium, generally choose 35 high quality carbon steel;

2. alloy steel

For medium and high pressure, when the medium temperature does not exceed 450 °C water, steam, excellent medium, 40Cr chromium steel is generally used for high pressure, medium temperature does not exceed 540 °C water, steam and other media, 38CrMoALA nitrided steel is used. For high pressure, medium temperature does not exceed 570 ° C steam medium, generally choose 25Cr2MoVA chromium molybdenum vanadium steel.

3.stainless acid-resistant steel S

For non-corrosive media and weak corrosive media with medium and high pressure, medium temperature ≤450 °C, 1Cr13, 2Cr13, 3Cr13 chrome stainless steel can be used. For corrosive media, stainless steel and acid-resistant steel such as Cr17nI2, 1Cr18Ni9Ti, Cr18Ni12Mo2Ti, Cr18Ni12Mo3Ti and PH15-7Mo precipitation hardening steel are available.

4.acid-resistant steel

For high temperature valves with medium temperature ≤600 °C, 4Cr10Si2Mo martensitic heat-resistant steel and 4Cr14Ni14W2Mo austenitic heat-resistant steel can be used.

Stem nut material

The valve stem nut directly receives the axial force of the valve stem during the opening and closing process of the valve, so it must have a certain strength, and it is threaded with the valve stem, requiring a small friction coefficient, no rusting and avoiding seizure;

1.copper alloy

Copper alloy has a small friction coefficient and is not easy to rust. It is one of the commonly used materials. For low pressure valves with Pg<1.6MPa, ZHMn58-2-2 cast brass can be used. For medium pressure valves of Pg16-6.4MPa, ZQAL9-4 tin-free bronze can be used, and for high pressure valves, ZHAL66-6-3-2 cast brass can be used;

2.Steel

When the working conditions do not allow the use of copper alloy, 35, 40 and other high-quality carbon steel, 2Cr13, 1Cr18Ni9, Cr17Ni2 and other stainless acid-resistant steel can be selected. Uneven working conditions refer to the following conditions:

- For the electric valve, the stem nut with the melon clutch needs to be heat treated to obtain higher hardness or surface hardness.

- When the working medium or the surrounding environment is not suitable for the selection of copper alloy, such as the ammonia medium which is corrosive to copper, when selecting the steel stem nut, pay special attention to the seizure phenomenon of the thread;

Fillers and gasket materials

The fasteners mainly include bolts, studs and nuts. The fasteners directly bear the pressure on the valve, which plays a vital role in preventing the outflow of the medium. Therefore, the materials selected must ensure sufficient strength at the use temperature. Impact toughness.

PTJ Shop specializes in the processing of high-quality CNC machine tools. The products include robot parts, valve parts, shaft parts, auto parts, aviation parts, automation parts, etc. The company has more than 100 sets of precision CNC machine tools to provide you with valve precision parts customization and Batch processing services.

|

PTJ Machining Capabilities |

|

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about cnc machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off