How many levels of precision can a lathe machining reach?

How many levels of precision can a lathe machining reach?

| The scale accuracy is still the roughness accuracy and the shape and position official grade accuracy. The machine tool can control the scale accuracy by 0.01mm. |

1. Regarding roughness up to 1.6

About shape and position official service such as coaxiality, concentricity, runout, straightness. Flatness and verticality can ensure the following ranges; Outer circle accuracy 0.01 Outer cylindricality 0.01 / 100 Face flatness 0.02 / 200 Thread pitch accuracy 0.06 / 300

2. Generally, the precision in mechanical machining refers to four points:

- 1.Scale public service

- 2.Shape degree public service

- 3.Azimuth official service

3. Surface finish (As for the flow of other largest physical scales, it is a concept that has only recently emerged. You did not say that the ordinary car is the highest machining accuracy of the ordinary car on the CNC car. The cnc machining accuracy is higher, but this is not certain, such as the external cylindrical service 0.01-0.02mm. Usually can be reached by lathes. In addition to the accuracy scale of the external circle, it also depends on the requirements of the external surface finish of the drawing. But the finish may be higher at 0.8, so you can't choose a lathe, you should choose a grinder. Sometimes the drawings require the scale to be in the range of 0.01-0.05. You can choose lathes, CNCs, milling machines, machining centers, but if you have higher requirements for coaxiality, perpendicularity, parallelism, you must consider Grinding may be another machine. Generally, the better lathe turning machining can be the highest grade 6 public service belt products.

|

PTJ Machining Capabilities |

|

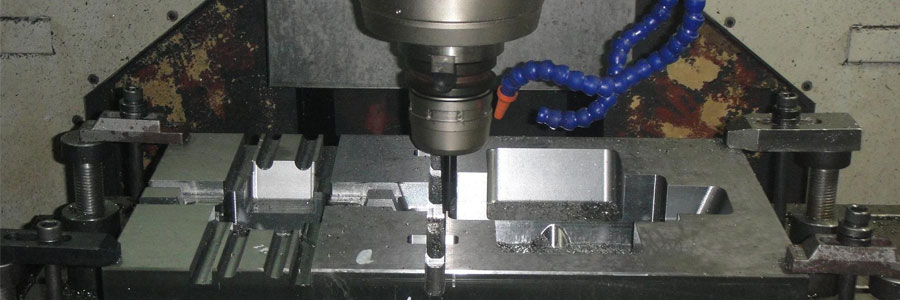

Automatic Bar Machining – Multi-spindle cam automatic screw machines CNC Turning – CNC delivers peak cost efficiency in shorter volumes, as well as high capacity production of mechanically simple components Custom Machining - with up to 12 axes of control Multi Spindle Machining- ISO 9001:2015 certified Screw Machine Products – The number of customized production parts per hour can reach 10000pcs Swiss Machining – with up to 9 axes of CNC control, to produce precision components with complex geometries in one operation High Volume Machining – 100 Advanced Production Turning Bar Automatics On-line and Ready CNC Milling - Machining Fully compliant with the exacting requirements of our customers 5 axis (11 axis) Machining – Tolerance | 0.1mm alignment |

What Can we help you do next?

∇ Get more information about Cnc Machining Shop

→Case study-Find out what we have done.

→Ralated tips about cnc machining services

By PTJ Manufacturing Shop|Categories: Blog|Tags: cnc milling services, cnc turning services, milling parts, turning parts, machining parts, special parts,faqs,technical news,company news,material news |Comments Off